In 2011, Red Brick Clothing started with our first vinyl cutter and heat press. Over the last 10 years, we have added a commercial inkjet printer/cutter and expanded our single-head heat press to a dual-head. We have the capacity to print orders large and small in-house! The main advantages of heat pressing is being able to handle specialty prints on tougher substrates like masks, bags, shorts and aprons and also doing custom names & numbers on team uniforms.

Heat pressing is a highly customizable printing option. Since the design is printed out on a commerical digital printer, you have the ability to print in full-color. Unlike screenprinting, the cost is not determined by the amount of colors used. The printed (and cut-out) design is then applied to the garment with high heat and pressure.

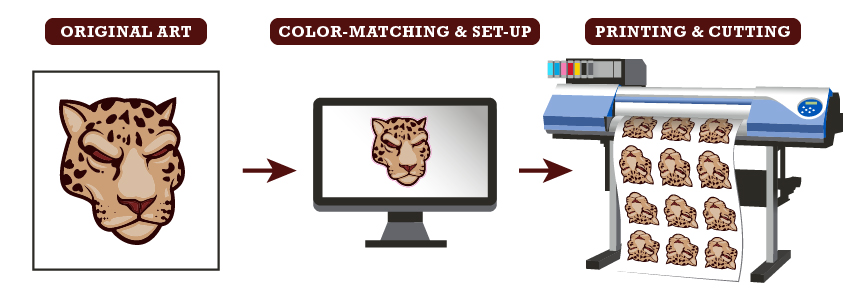

Here’s a breakdown of the process:

In order to heat press your design, we specifically set-up your artwork to be printed and then cut-out by our special printer. Our art department modifies your vectored artwork by color-matching specific colors if needed and adding a cut-line to the design. Our machine prints the design and then cuts the design out.

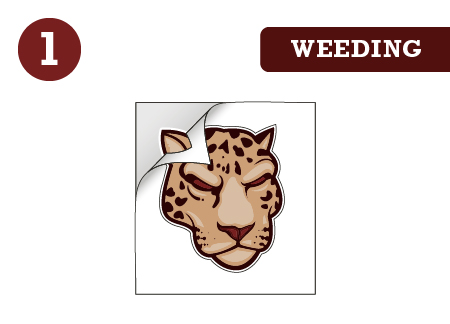

Weeding the Excess Material

The design is printed on a special material that sits on a backing, called a carrier. Once printed and cut, the excess material must be removed from each imprint. This process is called “weeding”. Once weeded, the design is masked with a transparent material so that the design can be removed from the carrier and placed on a shirt.

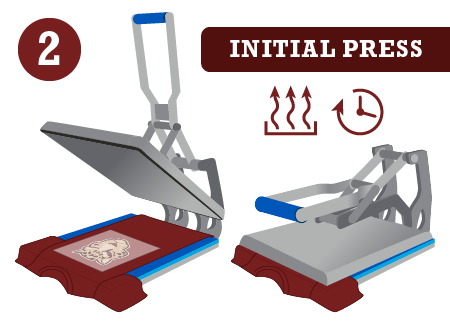

The Initial Press

The garment to-be-decorated is placed on the machine and the masked design is then positioned on the garment. The clear nature of the mask allows us to place it exactly to customer or industry specifications. Once the design is set, the press is closed and high heat and pressure are used to adhere the design to the garment.

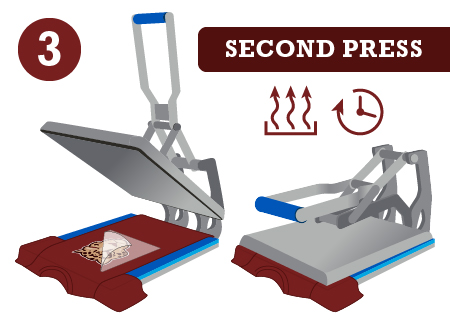

The Second (Insurance) Press

After the initial press, the mask is removed and replaced with a special paper sheet to protect the design. The garment and design then receive another press to ensure that the design is fully adhered.

The Final Product

Once the garment and design have been pressed twice, the final product is ready. Items get folded and bagged/boxed and are ready for you to pick-up.